News

-

15.10.2025 - Proxxon provides WinPC-NC parameters for CU4 control Open or Close

We are pleased to announce that the widely used and popular 4-axis CU4 control from Proxxon is now being equipped by the manufacturer with default settings for our WinPC-NC control program, which can be downloaded directly from the Proxxon website.The CU4 can be used to control a wide range of CNC and lathes from Proxxon, as well as other third-party CNC machines, and it is extremely reliable and delivers absolutely smooth movements.This means that all versions of our WinPC-NC, with its wide range of functions and many useful and intuitive features, can be used with this innovative control system.The following instructions will show you how to load the Proxxon presets or the presets of other manufacturers:Here is the link to the Proxxon homepage and the presettings:

-

31.01.2025 - WinPC-NC NET - 30-day trial with money-back guarantee Open or Close

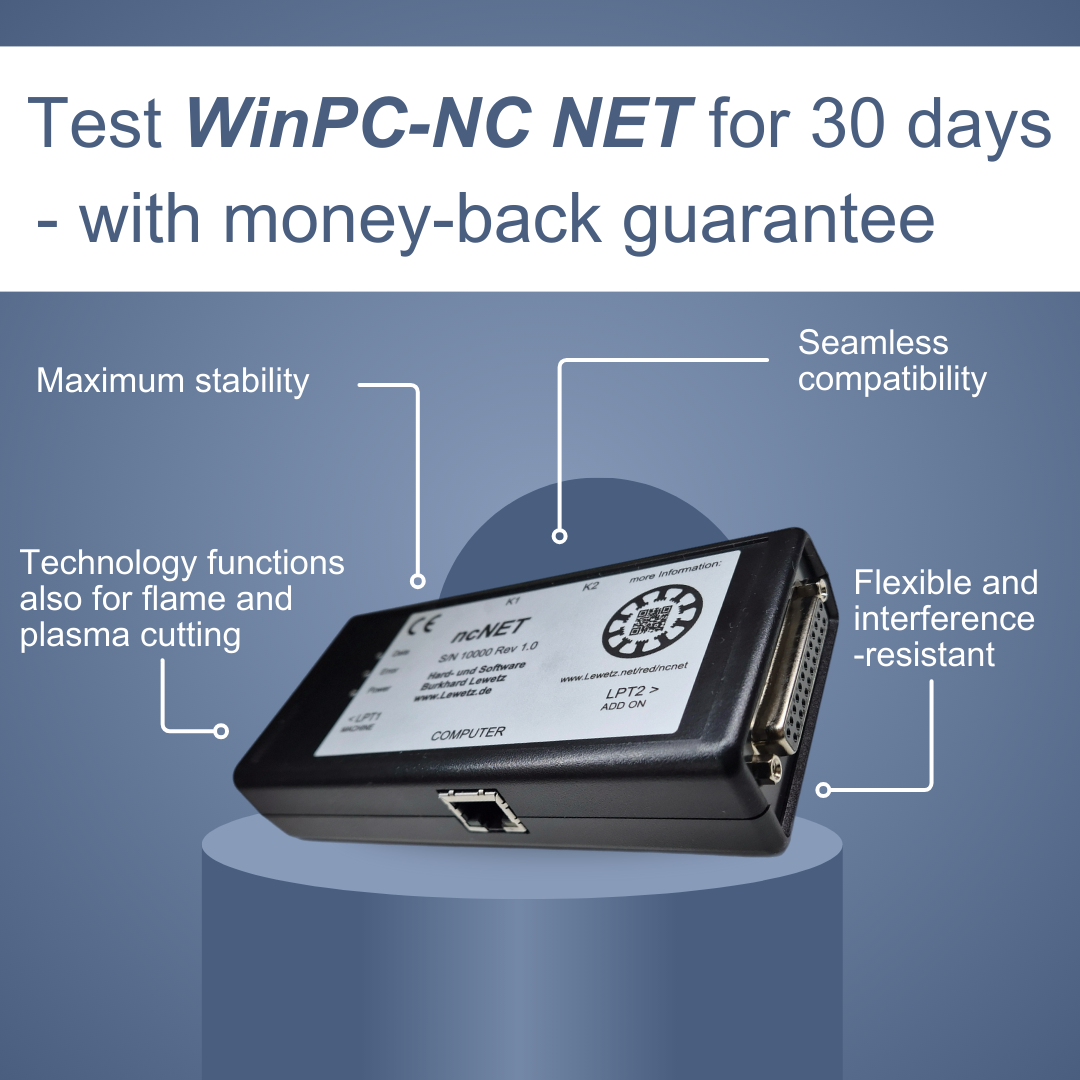

Our latest variant, WinPC-NC NET, has been available since last year and has already impressed numerous customers.

With our current promotion, you have the opportunity to test WinPC-NC NET including the ncNET module without obligation - and with a 30-day money-back guarantee. Convince yourself of the advantages of this innovative solution!

Who can benefit from the campaign?

- All users who are already using another WinPC-NC variant and would like to switch to WinPC-NC NET.

- Anyone who is currently using another software solution and would like to get to know the intuitive operation of WinPC-NC NET.

How the 30-day test campaign works

- Time slot: OrderWinPC-NC NET in the period 01.02.2025 to 28.02.2025 at the regular price in our online store.

- Free shipping:Your order will be delivered as quickly as possible and free of charge*.

- Test without obligation:Test WinPC-NC NET for 30 days from receipt of delivery without obligation and at your own speed.

- Money-back guarantee:

- If WinPC-NC NET convinces you, you keep the product.

- Otherwise, you can return WinPC-NC NET and the ncNET module free of charge* using the return label. We will refund you the full amount of the order upon receipt.

Special upgrade offer for WinPC-NC users

You already have another WinPC-NC variant and would like to switch to WinPC-NC NET and benefit from the discounted upgrade price?

- Try WinPC-NC NET for 30 days.

- Then return your previous WinPC-NC variant to us free of charge* using the return label.

- Upon receipt, we will refund you the upgrade differential amount.

Sample upgrade differential amounts:

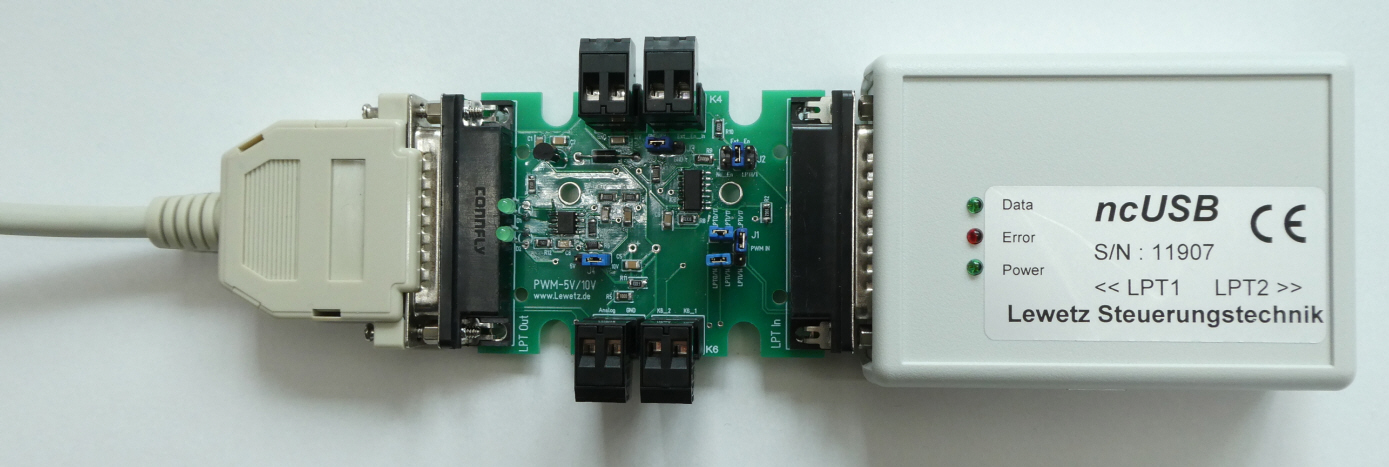

- WinPC-NC USB with ncUSB module:100 €

- WinPC-NC Economy with license dongle:60 €

- WinPC-NC USB with SC100B/SC100C module:80 €

- WinPC-NC Light with nc100 adapter:60 €

- WinPC-NC Light with CD:30 €

*Money-back guarantee and conditions:

- WinPC-NC NETwill be delivered free of charge during the promotional period 01.02.2025 to 28.02.2025.

- WinPC-NC NETcan be tested for 30 days after receipt.

- We will provide a free return label for returns from Germany or Austria.

- Customers from other countries can also take part in the promotion and receive an extended right of return of 30 days. For logistical reasons, we are unable to offer free returns.

- Returns and full refunds are only possible if the product is complete, intact and in functional condition when the return is received

- No more than one WinPC-NC NET can be tested per person as part of the promotion.

- No payment in cash or combination with other promotions

- The legal right of return is not affected by this guarantee and can be exercised independently of it.

Try WinPC-NC NET risk-free and

convince yourself of the innovative solution!

Don't miss this opportunity and experience WinPC-NC NET in action! > Test WinPC-NC NET now!

-

23.09.2024 - 15 years WinPC-NC USB and Anniversary discount Open or Close

We are proud to announce that WinPC-NC USB has been available for 15 years.

In the second half of 2009, we delivered the first WinPC-NC USB variants and thus laid the base for all current and modern WinPC-NC variants such as WinPC-NC Professional, USB, Light USB, Starter, USB for Stepcraft machines, USB for Hammer HNC machines and NET.

During this time, we have continuously developed WinPC-NC and the associated hardware and, in addition to many small improvements, have delivered major innovative steps with versions 2.5, 3.0, 3.1, 3.4, 4.0 and 4.1.

With all new functions and enhancements, we have always focused on full downward compatibility of our products in the past years, thus enabling all customers to easily and cost-effectively upgrade to the latest state of the art.

Many thousands of WinPC-NC licenses in the field, countless OEM projects with customer-specific solutions, the constantly positive feedback from our users and this year's awards of 1st place for “Best Service Quality” and 2nd place for “Highest Innovation” in the VTH reader survey confirm our work.

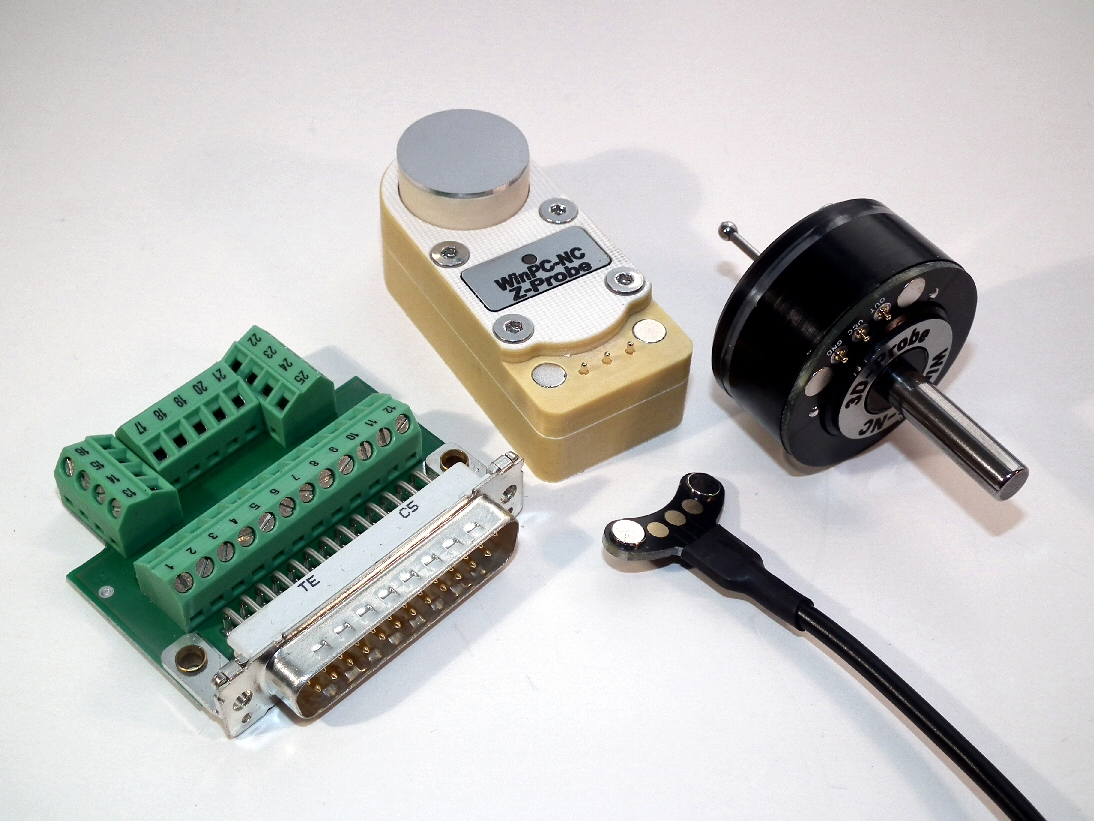

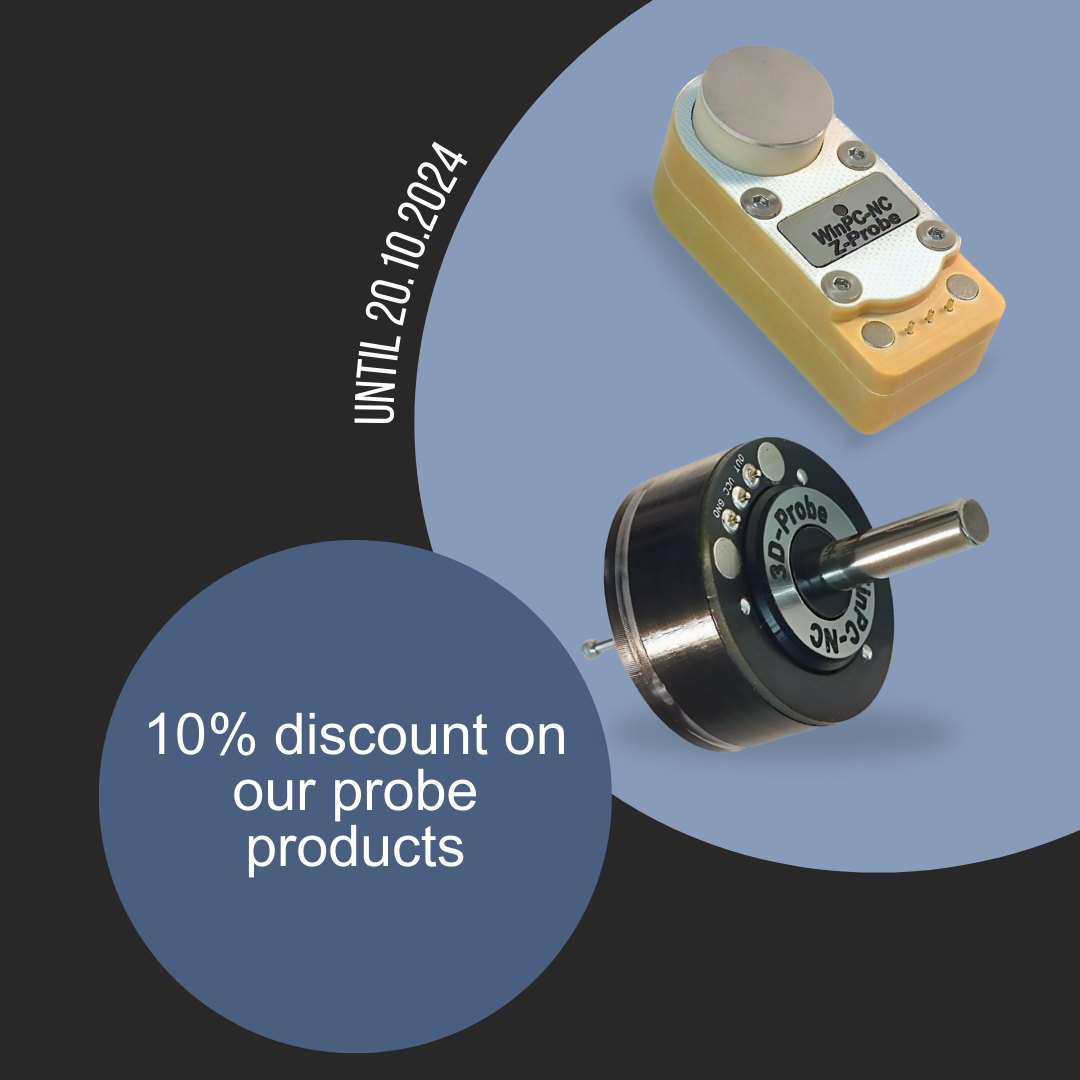

We would therefore like to thank all users, customers and partners and are offering WinPC-NC USB in our online store from 23.09.2024 at the anniversary price of 269 euros including VAT. Furthermore, we are extending the discount offer to our 3D and length probes and are offering them with a 10% discount on the gross sales price in the period from 23.09.2024 to 20.10.2024.Order WinPC-NC USB now Order probe now

-

17.07.2024 - Plasma cutting meets rotary axis: new user video Open or Close

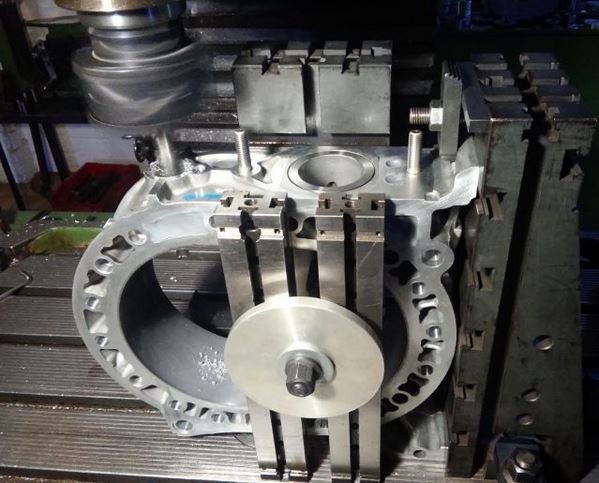

Plasma cutting meets rotary axis technology - with WinPC-NC and an in-house construction, our user, Vertulli Feinwerktechnik, cuts large pipes for further processing.

Watch the video here: https://youtu.be/d8DZ_UXjT1E?feature=shared

-

10.07.2024 - WinPC-NC NET impresses in practical test: Our testers are excited Open or Close

Today we are pleased to present you the first impressions and test reports on our latest product, WinPC-NC NET. Our testers have taken a close look at the product and are impressed by its quality and reliability. Here is some of the feedback we have received:

What our testers say about the new WinPC-NC NET:

„WinPC-NC NET runs reliably in continuous operation at our machine test station.“

– M. Pech from MechaPlus

„WinPC-NC has been upgraded with new hardware and will now also be available as a network version. I had the opportunity to test this new network version in advance and get my own opinion. My conclusion on the new net version: A great success. What I really liked was the simple and flexible connection to the network and the stable/interference-free connection.“

– UBO, CNC forum for hobby users

„So far the NET version is 100% stable, there have been no dropouts or other problems.“

– M. Zeller from KPF-Zeller

„The WinPC-NC NET version has been running very reliably and stable for weeks...“

– HubiFD, Hubis Holzstadl

„We have been using the new WinPC-NC NET for a few weeks now (30-40 hours) and there have been no faults.

The connection control to the PC is stable. We have a lot of milling work planned for the next few weeks, which we will be executing with WinPC-NC NET."

– M.Glock from MG-Produktionsfinish

This consistently positive feedback confirms us in our work and shows that WinPC-NC NET is a reliable and powerful solution for a wide range of applications.

We are proud of the result and are pleased that our testers are so enthusiastic.

Convince yourself of WinPC-NC NET now: www.Lewetz.net/red/nete -

20.06.2024 - WinPC-NC NET with ncNET module available from 15.07.2024 - pre-order now to get the introductory price Open or Close

We are pleased to announce that WinPC-NC NET with ncNET module will be available from July 15, 2024.

The network version of WinPC-NC promises maximum connectivity and outstanding performance for a wide range of applications.

Innovative features and benefits:

- High clock frequency: With an internal clock frequency of 168 MHz, the

- WinPC-NC NET with ncNET offers up to 8x faster motor clock signals than previous variants.

- · Stable network connection: Enables direct connection to the control computer or via network switch and hub for optimum stability.

- · Advanced technology functions: Integrated functions for flame and plasma cutting.

- · Versatile control options: Support for up to 4 axes with 5V TTL logic.

- · Robust inputs and outputs: 10 inputs with low-pass filter, Schmitt trigger and overvoltage-proof up to 38V DC. 16 digital outputs decoupled and amplified for maximum interference resistance and flexibility.

- · and much more.

Introductory price:

You can now pre-order WinPC-NC NET with ncNET at the introductory price of 279 Euro.

Or pre-order the upgrade from WinPC-NC USB to WinPC-NC NET at the special price of 179,- Euro.

The offer is valid until 15.07.2024. Delivery will begin on 15.07.2024.

The product is supplied with a high-quality 3m Ethernet cable and an external power supply unit and is therefore ready for immediate use.

This variant sets new standards in the WinPC-NC product family and offers an optimal solution for users who place the highest demands on connectivity and performance but still appreciate the simple and clear operation of WinPC-NC.

Further information and pre-orders are available at: https://lewetz.net/en/WinPC-NC-NET-with-ncNET/SW10110

For more information on upgrading from other WinPC-NC variants to WinPC-NC NET, go to: https://lewetz.net/en/WinPC-NC-NET-with-ncNET-Upgrade-from-other-WinPC-NC-variants/SW10114

-

21.12.2023 - Merry Christmas and a happy new year Open or Close

We would like to take this opportunity to send you our best wishes at the end of the year.With a festive glow and a grateful heart, we would like to wish you a Merry Christmas and peaceful holidays. Enjoy the festive atmosphere with your loved ones.A successful year 2023 lies behind us, and we are optimistic about 2024.We look forward to mastering the challenges ahead together with you. Your trust is both an incentive and an obligation for us. We are confident that 2024 will bring new opportunities and successes for us all.We appreciate the trust you have placed in us. We will continue to do everything we can to meet your expectations in the new year.Thank you for your support.Merry Christmas and a Happy New Year!Your team from Hard- und Software Burkhard Lewetz

We would like to take this opportunity to send you our best wishes at the end of the year.With a festive glow and a grateful heart, we would like to wish you a Merry Christmas and peaceful holidays. Enjoy the festive atmosphere with your loved ones.A successful year 2023 lies behind us, and we are optimistic about 2024.We look forward to mastering the challenges ahead together with you. Your trust is both an incentive and an obligation for us. We are confident that 2024 will bring new opportunities and successes for us all.We appreciate the trust you have placed in us. We will continue to do everything we can to meet your expectations in the new year.Thank you for your support.Merry Christmas and a Happy New Year!Your team from Hard- und Software Burkhard Lewetz -

11.12.2023 - New in our portfolio: Our HR-20 handwheel for your CNC machine Open or Close

We are pleased to present our latest product: the HR-20 handwheel, an efficient tool for CNC operation.

The handwheel is equipped with an ergonomic casing that optimizes operating comfort. It has a replaceable 3 m cable with USB plug and can be ideally stowed away on your CNC machines using the mounting bracket.

The axes are selected via a convenient rotary switch and the handwheel is automatically recognized by Windows. Commissioning is simple and only requires activation in the WinPC-NC parameters. The HR-20 handwheel offers precise positioning, step-by-step movement, job control and spindle control.

The product is compatible with all WinPC-NC variants from version 3 or higher. Further information can be found in the info sheet.

The HR-20 handwheel is now available in our online store. Order now and optimize your CNC operation! Buy now -

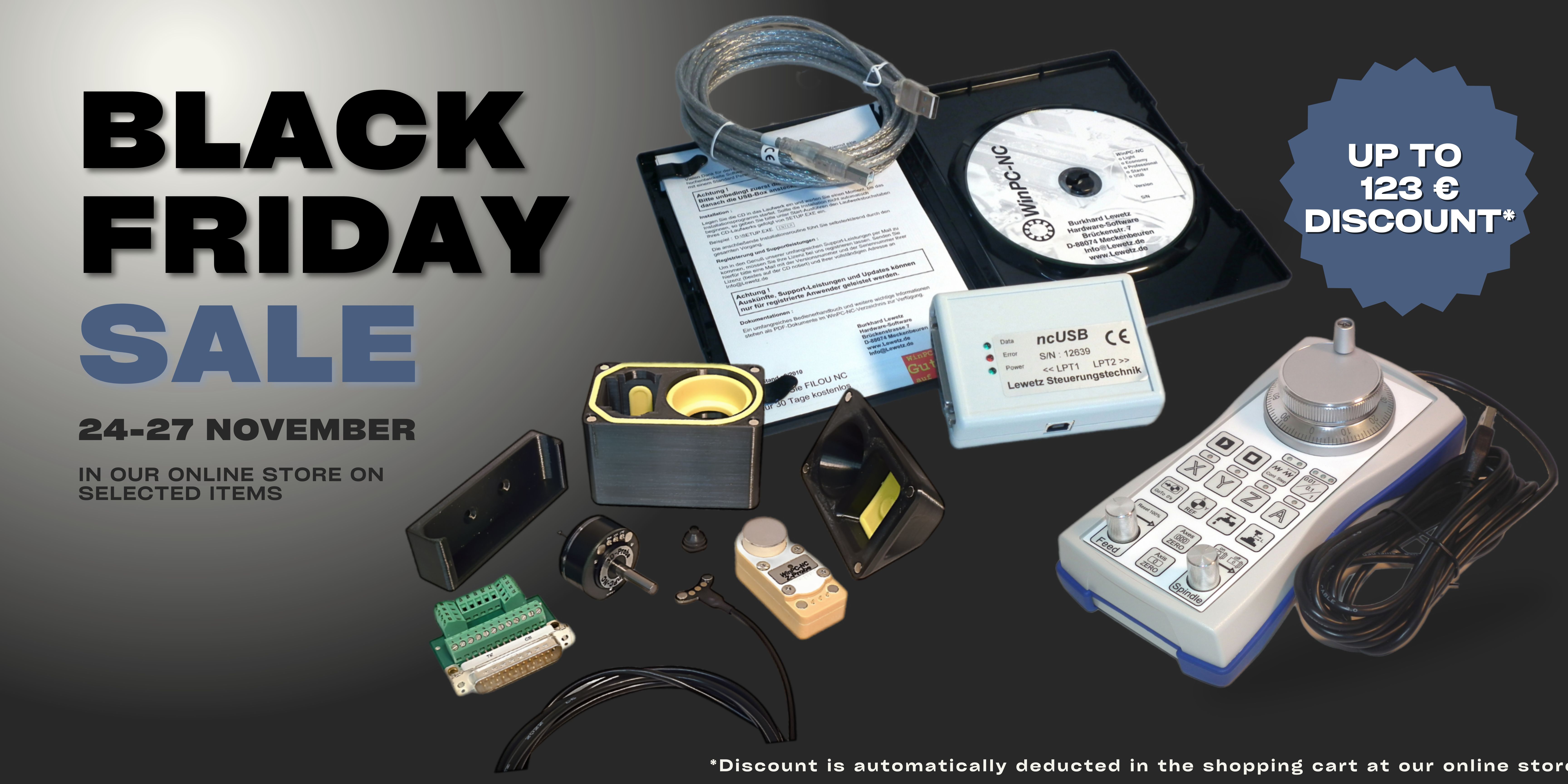

18.11.2023 - Black Friday Deals - Up to €123 discount on selected items!* Open or Close

From 24.11.2023 until Cyber-Monday (27.11.2023) there are discounts on the following items in our online store, www.Lewetz.net:

WinPC-NC USB in combination with the pendant HR-10 for 448 € instead 548 € - You save 100 €*

WinPC-NC USB in combination with the 3D-Probe and Z-Probe Bundle for 438 € instead 528 € - You save 90 €*

3D-probe 3D-Probe for 126 € instead 149 € - You save 23 €*

3D-Probe and Z-Probe Bundle for 206 € instead 229 € - You save 23 €*

Pendant HR-10 for 226 € instead 249 € - You save 23 €*

Simply add the desired items to your shopping cart in our online store on Friday, 24.11.2023 and the discount will be deducted automatically!

*All prices in euros and including VAT. The sales price on which the discount is based is the regular sales price charged by us outside of the discount promotion. The discounts are valid from 25.11.2023 to 27.11.2023 and are automatically deducted in the shopping cart and at the checkout in our online store at www.Lewetz.net. The discounts cannot be combined with other vouchers. Only one discount can be applied to an item. No cash payment. If one of the combined items is returned in order to obtain the discount, the discount loses its validity and the regular price for the goods remaining with the customer will be charged.

-

16.05.2023 - The update 4.1 of WinPC-NC: Available since 4 weeks and inspires with positive feedback! Open or Close

Version 4.1 of WinPC-NC has been available for four weeks now and we have received only positive feedback from our customers so far.

On YouTube we have published a video summarizing all new features. Here you can find the video: to the YouTube video

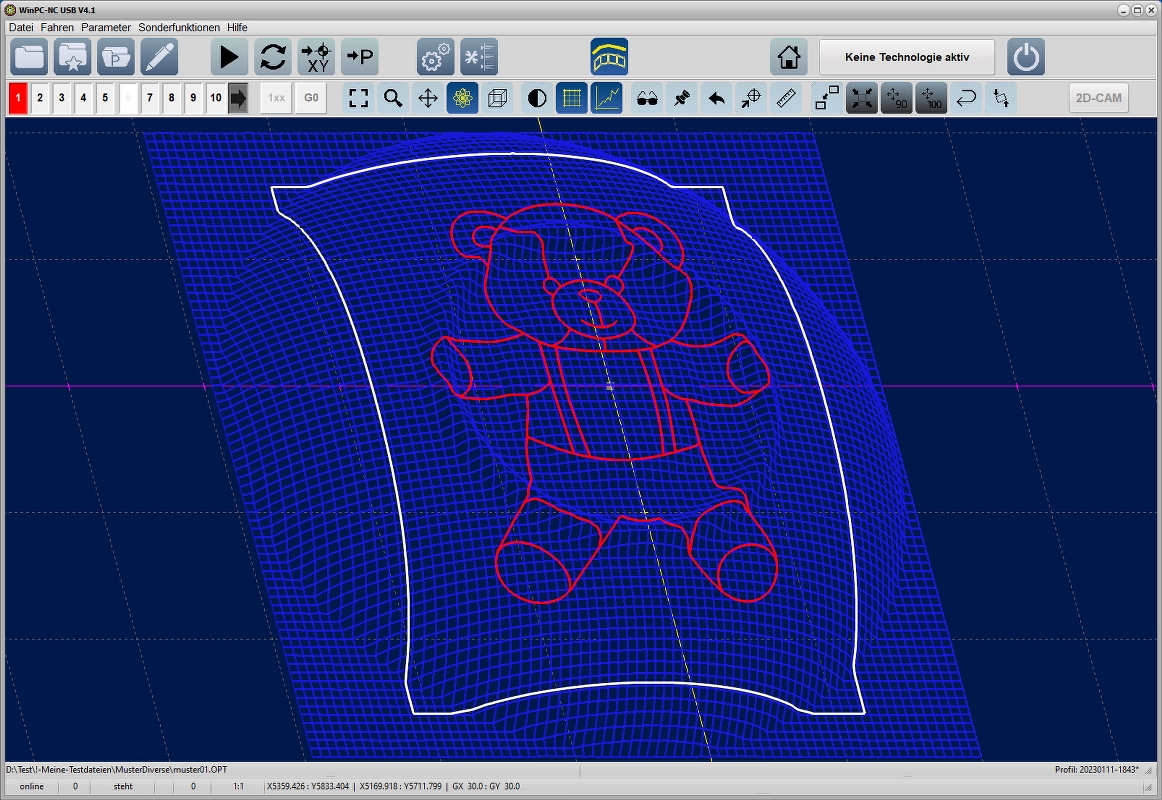

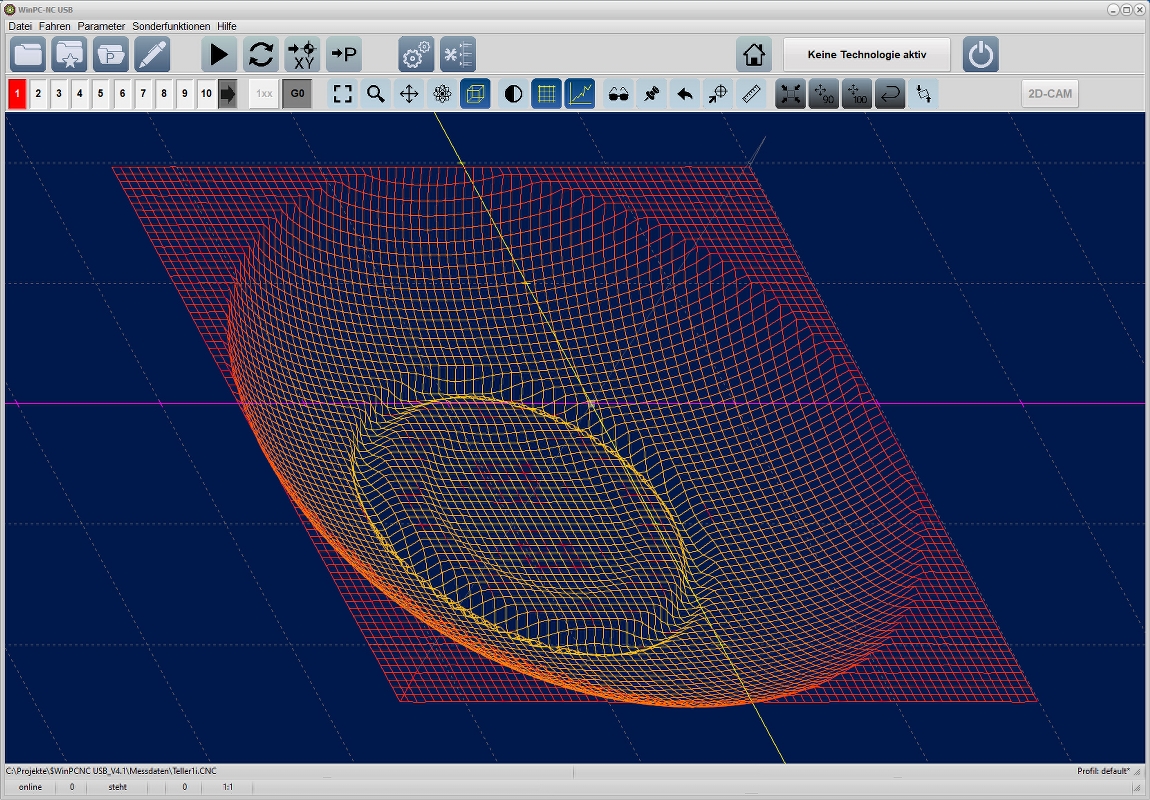

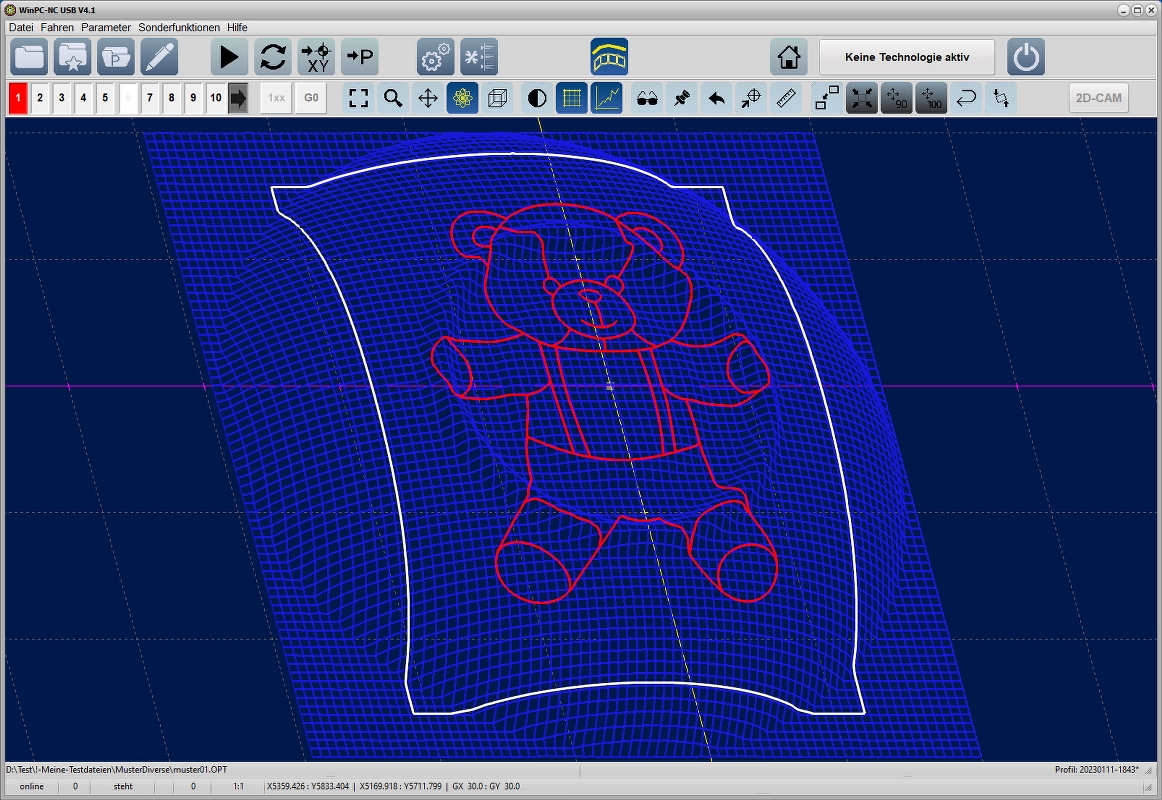

Highlights of the new version 4.1 include, for example, scanning of non-planar surfaces and projection of data on them.

So if you haven't switched to the new update yet- it's definitely worth it!

With version 4.1 of WinPC-NC, you have a powerful software at your fingertips that will help you implement your projects quickly and with precision.

Also feel free to follow us on our social media channels (Instagram, Facebook and YouTube) or sign up for our newsletter (to the registration form), this will give you a quick overview of what's new.

The update to the new version 4.1 is free of charge for all users of version 4.0 and possible directly via the download area of our website. Detailed instructions for the update can be found here.

Users of version 2 and 3 of WinPC-NC can order the update to version 4 here in our onlineshop. -

26.04.2023 - WinPC-NC is compatible with a wide range of CNC machines Open or Close

Discover WinPC-NC's compatibility with a wide range of machine manufacturers such as Stepcraft, CNC-Modellbau / MechaPlus, Sorotec, Haase, CNC-Step, GoCNC, Bulldog CNC, Hammer HNC, ISEL, StepFour and many others. WinPC-NC gives you a seamless connection and a perfect user experience.

For many of the machines from these manufacturers, we have predefined parameter sets, which makes switching or commissioning much easier.

Get access to this world-class software now and experience the ultimate control of your CNC machine! -

17.04.2023 - New version 4.1 of WinPC-NC available Open or Close

We are pleased to present the new version 4.1 of WinPC-NC. The new version offers numerous new functions and enhancements that make your work with WinPC-NC even easier and more efficient.

The update to the new version 4.1 is free of charge for all users of version 4.0 and possible directly via the download area of our website. Detailed instructions for the update can be found here.

We have summarised the new functions of version 4.1 for you again in a video. You can find the video here on our german Youtube channel.

The new features at a glance:

-Scanning of non-planar surfaces and projection.

-Definition of critical or protected areas

-Ethernet connection of the CNCCON axis controller instead of serial and USB

-Easy moving of NC data within machine working area

-Test measurements for tools -Tool breakage control

-Output signals when axes are in certain positions

-Fixed surface probe and definition of material thickness

-User management and password protection

-Minor changes and enhancements

The new functions are summarised here with pictures as a PDF. -

13.03.2023 - Our new newsletter - Don't miss any more news! Open or Close

We are pleased to inform you that we now offer a newsletter. With this, we would like to keep you up to date on news, offers and promotions.

As a newsletter subscriber, you will now also receive regular information on current topics from our company by e-mail.

If you are interested in our newsletter, you can easily register.

Register now for the newsletter in our online shop*.

Of course, the registration is free of charge and without commitment.

Should you no longer wish to receive news from us, you can easily unsubscribe at any time.

*You will be redirected to the registration form. -

09.03.2023 - The sensors 3D-Probe and Z-Probe in a bundle for the introductory price Open or Close

The sensors 3D-Probe and Z-Probe in a bundle

- reach new demensions in nautomated measurement.

Automated measuring for better work results with the 3D-Probe and Z-Probe Bundle.

Use the 3D-Probe to comfortably set up your workpiece or to measure and compensate a not even surface.

Measure the Z zero point of your workpiece with the flying Z-Probe or use the probe fixed mounted on your CNC machine to compensate different tool lengths.

Both probes are conveniently connected with a magnetic clip and the same cable and thus require one input only.

Highlights of the 3D-Probe and Z-Probe:

- Repeatability <0.007mm (Z-Probe) and <0.03 (3D-Probe)

- Supply voltage 5-24VDC, already integrated in WinPC-NC hardware

- NPN switching output as normally closed contact with max. 50mA switching current

- Required accessories and manual included in scope of delivery

Measure lengths and positions easily with the 3D-Probe and the Z-Probe now!

Directly available in our online shop: 3D-Probe and Z-Probe Bundle

-

13.02.2023 - New "How to" Open or Close

We have new "How to" available for you.

Please have a look and see if there is any help for you. -

21.12.2022 - Merry Christmas Open or Close

We wish you all a Merry Christmas and a good start into a successful new year 2023.

We would like to thank all our users, customers and partners for the good cooperation in this difficult year. This year some new features were released in version 4 of WinPC-NC and major further developments were started.

Our office will be closed from December 23rd to January 9th and we will not be reachable by phone during this time. However, your e-mail inquiries will be processed as soon as possible during this time.

Burkhard Lewetz and team -

27.07.2022 - Modellbau-Award of the VTH publisher Open or Close

This year the readers of Maschinen im Modellbau magazine were again surveyed and at this year's award ceremony we achieved second place three times with our WinPC-NC in the categories "Highest Innovation", "Highest Product Quality" and "Best Service Quality".

We would like to thank all readers of the magazine and our users for this evaluation and assure you that we will continue to work for you and WinPC-NC with all our commitment in the future.

-

13.05.2022 - WinPC-NC on computers with ARM processors Open or Close

Computers with ARM processors such as laptops or development boards with Windows installation are currently being offered more and more frequently by various suppliers. However, these computers only run a special version of Windows which only rudimentarily and inadequately integrates the necessary drivers.

For our WinPC-NC USB, a widely used driver from FTDI is used for the hardware connection. Despite the provision of a variant for ARM processors, we were currently unable to find a Windows installation on an ARM computer in our test laboratory with the real-time requirements and driver support necessary for CNC machining.

We therefore advise against the use of computers with ARM processors and recommend the use of an Intel or AMD processor.

WinPC-NC Professional is executable under the Windows variant for ARM processors.

Nevertheless, we still recommend the use of a standard computer with a suitable Intel or AMD processor due to the usually lower computing power. -

05.04.2022 - We can still deliver without problems Open or Close

Despite generally known supply problems for electronic products, we are still able to deliver and can supply almost all of our products from stock through forward-looking procurement of important parts.

Especially our standard products WinPC-NC USB and WinPC-NC Professional with the controllers in various housings and expansion stages are available at short notice or directly from stock. -

01.03.2022 - Keypad KP-10 as an alternative to the pendant HR-10 Open or Close

As an alternative to our proven HR-10 pendant, we offer the KP-10 keypad, a low-cost solution for setting up your CNC machine with WinPC-NC. The Keypad KP-10 is perfect for all users who do not need a handwheel for setup. The Keypad KP-10 is connected to the control computer via Bluetooth and can be integrated directly into WinPC-NC.

The meaningful lettering on the keys is printed directly on the keys for maximum abrasion resistance.

The functions and keys are based on the instructions for making your own keypad that were made available several years ago.

You can find the keypad KP-10 with further information in our shop. -

04.02.2022 - WinPC-NC for HAMMER HNC 47.82 Open or Close

To control the HAMMER HNC 47.82 and 47.82 HF with our WinPC-NC, we have developed an adapted control box based on our ncUSB module.

The software and hardware does not differ from the widely used WinPC-NC USB software and has been adapted to the special pinout of the HAMMER HNC machine.

The necessary and optimised machine parameters were determined by us and are included in the scope of delivery.

On the hardware supplied, a switch can be made between outputting the control signal for spindle speed control as a PWM signal or a 0-10V analogue signal. This means that both Hammer HNC 47.82 and Hammer HNC 47.82 HF versions can be used.

WinPC-NC USB also supports the control of an additional 4-axis and offers 3 more inputs and 4 more outputs at the add-on connector for the connection of external components.You will find the WinPC-NC USB for HAMMER HNC in our shop with additional information.

-

15.12.2021 - Merry Christmas Open or Close

We would like to take this opportunity to thank all our users, customers and partners for the good cooperation this year. We have released many new functions and the new version 4 of WinPC-NC this year. Next year you can look forward to many new functions and enhancements.

We wish you and your families a Merry Christmas and a good start into the new year 2022.

Our office will be closed from 23 December to 10 January and we will not be available by phone during this time. Your enquiries by e-mail will be processed as quickly as possible during this time.

Burkhard Lewetz and Team -

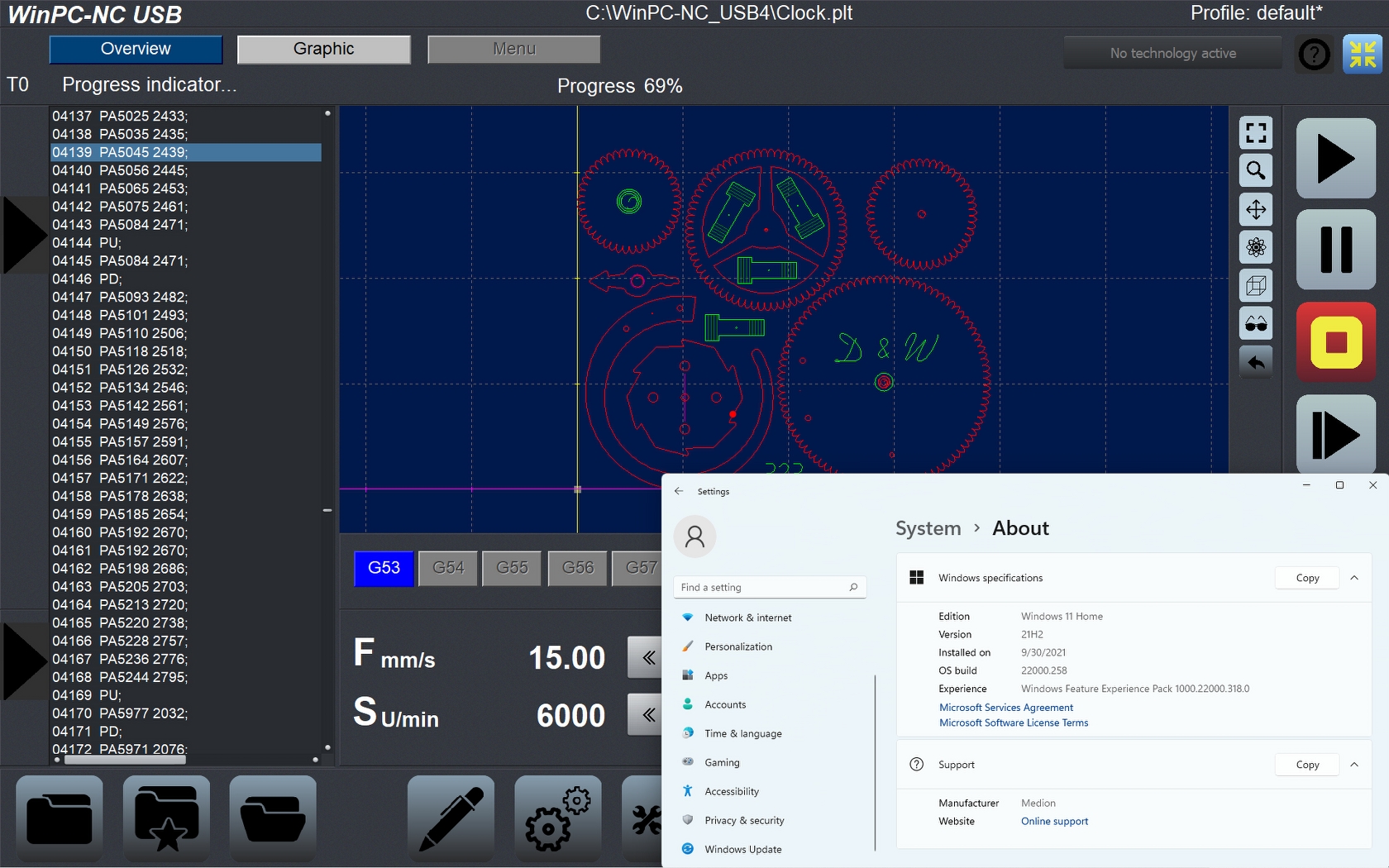

12.10.2021 - WinPC-NC and Windows 11 Open or Close

Microsoft published the new operation system Windows 11 on the 5th october 2021 for end- and business customers.

We tested the new Windows 11 with our WinPC-NC and the current version 4 of WinPC-NC is completely compatible with Windows 11. You can change to the new operation system or buy new hardware with Windows 11 pre installed without any concerns.

All current versions of WinPC-NC are delivered with external hardware which solves the real time tasks. That allows you to change the operation system without any big changes.

-

11.08.2021 - Looking for staff: software engineers and support stafff Open or Close

We are looking for two software engineers to support and complete our team.

You are the right candidate for the job, if you are interested in CNC technics, model construction, Maker projects as well as in professional automation. Preferably you are experienced in programming with Visual Studio, Embarcadero RAD-Studio and C++. Specific qualifications concerning Embedded, programming micro-controllers and fieldbus interface are also required. If you want to realize your know-how in our innovative team, please send us your full application by mail to application@lewetz.de. We offer an interesting and varied job in one of the leading tourist regions in Germany – on Lake Constance.

Please contact us for specific job details by mail or phone without any obligation. We will be pleased to provide further detailed information.

-

30.07.2021 - Video of WinPC-NC version 4 Open or Close

Right in time to the introduction of the latest WinPC-NC version 4, one of our power users, UBO from UBO-CNC, captured in short on video the innovations of the user interface. We express our sincere thanks to UBO for this presentation and the excellent timing.

-

28.07.2021 - WinPC-NC 4.0 Open or Close

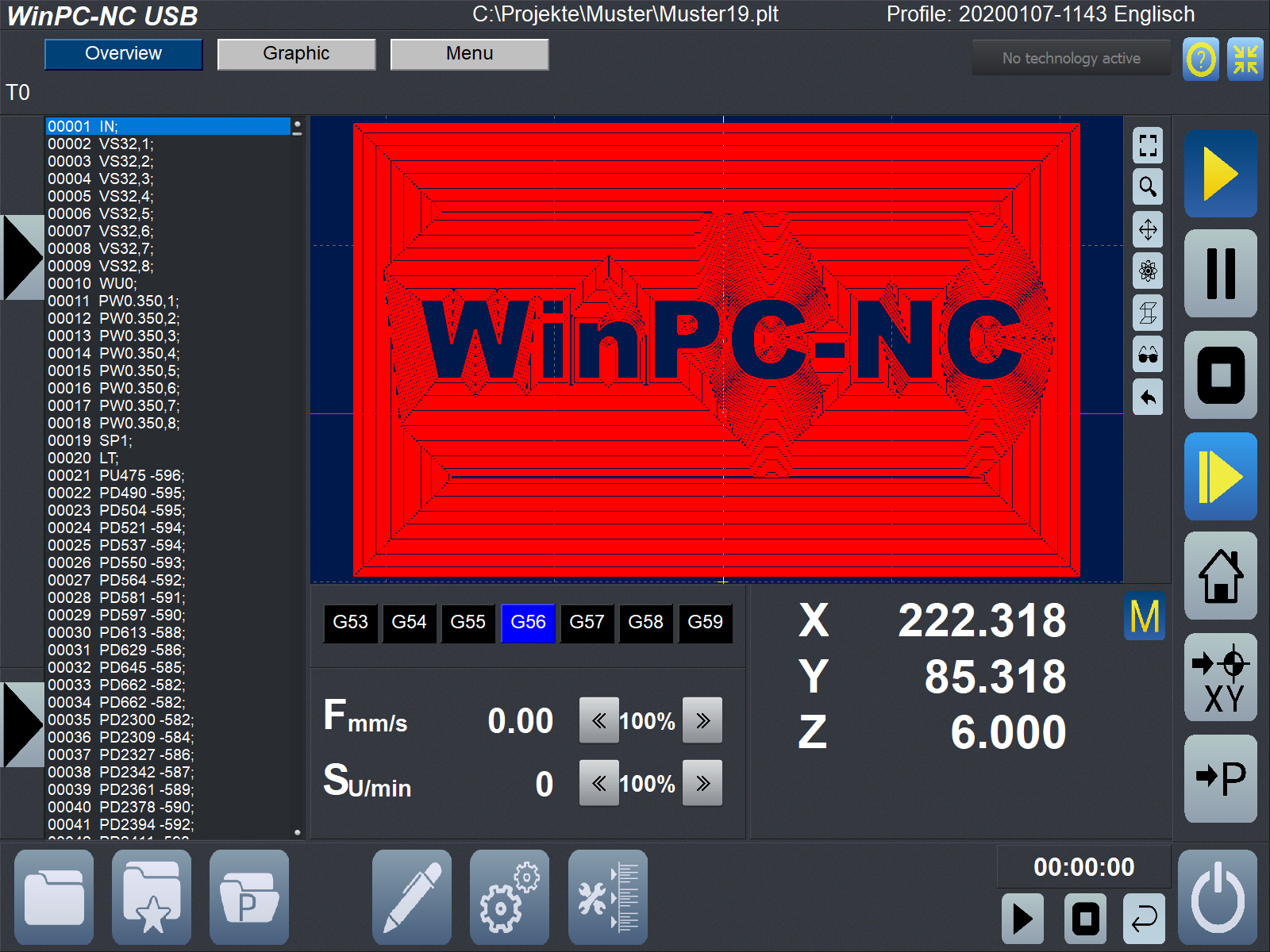

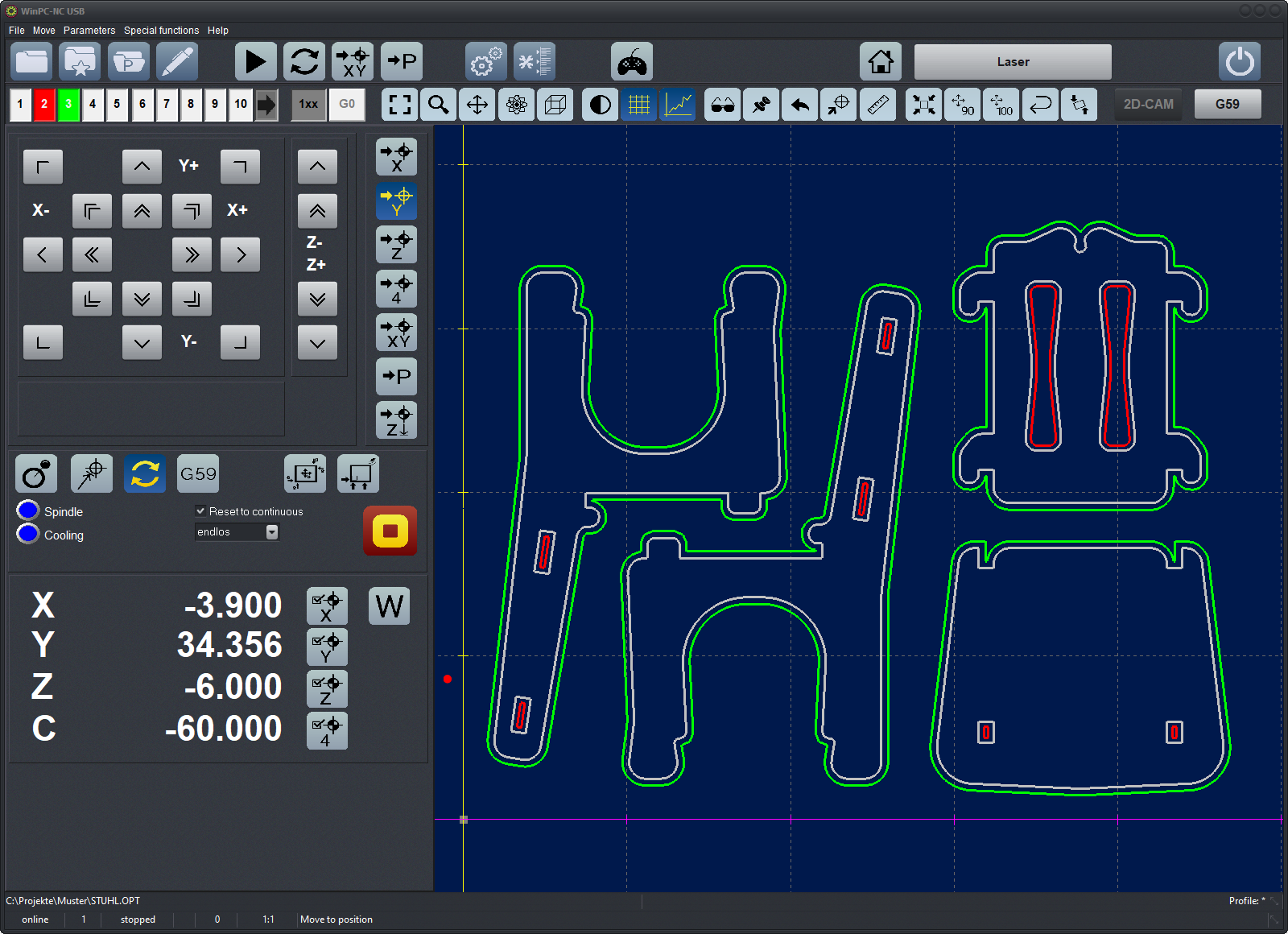

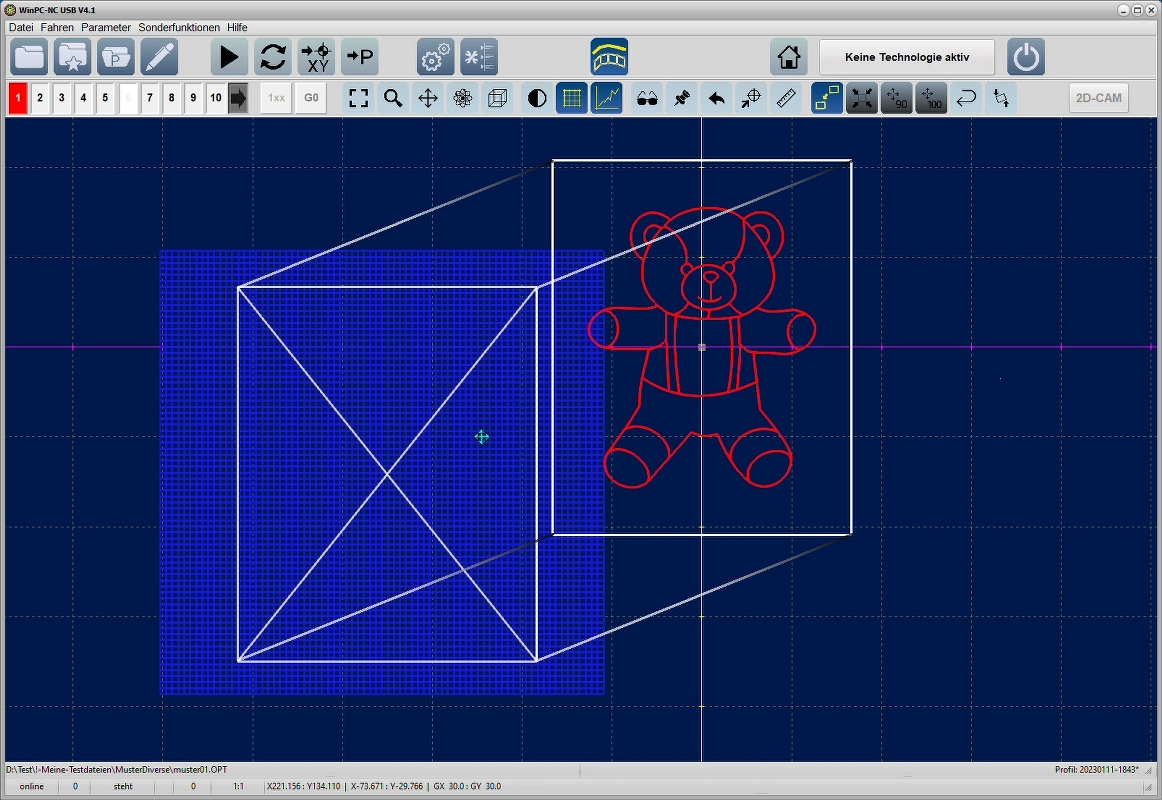

As of today, the new version 4 of our WinPC-NC control program is available and ready for delivery. Based on an intensive development period and extensive tests during more than 2,5 years and by integrating the latest technical and engineering know-how, we are pleased to present WinPC-NC Professional, WinPC-NC USB, WinPC-NC Light with nc100 adapter and WinPC-NC Starter in a new design together with innovations and improved features.

Besides the well-known user interface of version 3, version 4 provides advanced settings with permanent side panel for direct machine operation and set-up as well as a touch screen optimized view with a new operational concept.

WinPC-NC touch-optimized user interface

WinPC-NC classic view with new side panel

Here are the most important new features:

- New and consistent buttons with clearly defined symbols

- New button layout for easy and user-friendly handling

- Optionally 3 different views according to the individual requirements: standard view version 3, standard view with side panel for direct operation of axes and a touch screen optimized view with a new layout of the user interface

- Individually definable styles for personalizing the user interface

- Real-time display with current feed rate and spindle speed

- 2D-CAM functions with radius compensation and start distance

- Recently used files can be directly activated via mouse or touch click

- Saving last position

- Precise homing

- Spindle warm up function

- New and substantially revised manual

- New and enormously enhanced technology functions

- Improved contouring control system

- And much more besides

Detailed information concerning the new functions and descriptive illustrations can be obtained as PDF for download here.

The update can be directly ordered by a click here in our german online shop. Otherwise the update can be ordered via e-mail at info@lewetz.de. Subsequently the update is available by a download link including set-up instructions and information on features of the new version. Please note: The previous or existing software is compatible to the new version and parallel operation does not cause any trouble. Personalized parameters can be easily transferred via profile after installation without the necessity of being set up again. Detailed information on parameter transfer can be obtained in the category HowTo with WinPC-NC as PDF for download.

-

18.05.2021 - Customized solutions with WinPC-NC and other components, e. g. CNC machine with 4 Z-axes Open or Close

Despite various options concerning parameter settings and potential applications of our standard products, we are sometimes contacted by customers regarding specific applications. In the last years we managed to satisfy most of these inquiries by creating customized solutions with minimum efforts and by extending our standard products. Generally, it concerns specific positioning and production procedures with path-controlled mechanics and CNC machines or it is intended to integrate them into a sophisticated complete system.

For integrating path-controlled motions or CNC operation into a production process, we standardly provide some options for synchronization. The spectrum ranges from control commands concerning operation, automated background processing up to the programming interface of our WinPC-NC Professional axis controller.

We are pleased to present in short some of our latest projects in order to outline additional options of our standard products WinPC-NC and WinPOSI and to illustrate the variety of functions for realizing individual projects.

CNC control unit with four Z-axes

We developed and manufactured a complete control system with 8 motor drivers for a CNC machine with four Z-axes based on the approved and tested CNCMAX. For this control unit we produced an intelligent board which manages administrative tasks and the change-over of different Z-axes. Synchronization of the individual Z-axes, inclusively homing and selection is comfortably made by macros which are applicable in many cases in WinPC-NC. Each of the four Z-axes are equipped with various tools and can be used fully automatically within a job.

Industry 4.0 projects with integration of the WinPC-NC system to higher-level control systems

In the last years there was a constant increase of projects which have been realized by using the well-known keywords Industry4.0 and interconnection of production. This means integration of CNC operation into a complex job process. Applications comprise the automatic feeding, external production steps and specific host applications for individual processes and customer machines.

Laser cabin with laser marker

Recently we supplied a position controller and control interface for a laser cabin intended for automatic marking of single components. The used laser is equipped with a reflecting mirror for covering independently a wide workspace. The supplied unit controls the communication between laser control and position and moves along the defined positions according to the program settings. Due to simple programming with plaintext commands and non-cryptic G codes it is quite easy to refine or customize the products later on – and this is explicitly requested.

Are you interested in customized solutions for realizing specific projects?

Do you have to manage positioning tasks or intend to centralize various operational steps and create an all-in-one concept?

Do you wish any further information on the presented projects according to your requirements?

Please send a mail to Info@Lewetz.de by indicating basic information on your system and version. We would be pleased to submit a customized solution as soon as possible.

-

09.04.2021 - Current version as update Open or Close

Sometimes we are faced with queries and reports concerning irregularities with previous versions. In most cases we managed to eliminate these failures before the request and ask our customers to download the current version of the update.

Therefore we kindly ask you, to check our homepage from time to time for new versions in the category Service-Downloads.

Updates within the major versions V2.xx or V3.xx are still available for free and can be easily loaded and set up by oneself. Brief instructions are always available in the README file.

In WinPC-NC the actual used version is indicated in the “Help” menu ‘About WinPC.NC’.

-

18.02.2021 - Adapter for signal adaption Open or Close

We provide a varity of signal adapter to adjust the signals to extern components for different applications. The adapters are optionally available with DIN rail mount kit.

Adapter-C Junction of clock pulse signals and directional signals may be required for retrofitting Mach3 control units

SMC-Adapter

Conversion of clock pulse signals and directional signals into current application pulse for common SMC stepper motor cards

Double axis

boardControlling parallel arranged X or Y axes with automatic alignment on two

separate reference switchesPWM-Adapter

Conversion of the PWM signal into a real analog signal 0-5V or 0-10 V

Adapter-422 Conversion of simple clock pulse signals and directional signals into difference signals according to RS422

Boost-Adapter Amplifying all output signals up to 50mA, alternatively with level for 24V power stage outputs

Most of these adapters are combinable and can be plugged in a row. Please do not hesitate to contact us for your specific requirements. We are gladly prepared to assist you in realizing your individual projects.

-

17.12.2020 - Merry Christmas Open or Close

We wish all partners, clients and friends merry christmas after this challenging year 2020 and a good start into the new year 2021.

Our office is closed from the 21th december to the 6th january. Your e-mail requests will be answered as soon as possible during this time.

Burkhard Lewetz und Team -

21.09.2020 - Customer Application glass cutting with tangential knife Open or Close

A customer from Russia uses our WinPC-NC software to control his new glass cutting machines.

The video shows a test run in a mirror production facility with mirrors in different shapes.

WinPC-NC controls the 3 cartesian axes and the tangential knife to cut the glas plates. The plates can be cutted in different shapes from simple DXF drawings with more than 1m/sec speeds.

To improve the cutting result WinPC-NC controls a special liquid with its powerfull macro functions before the tangential knife is moving.

After the automatic cutting process the mirrors are seperated and sorted by hand. -

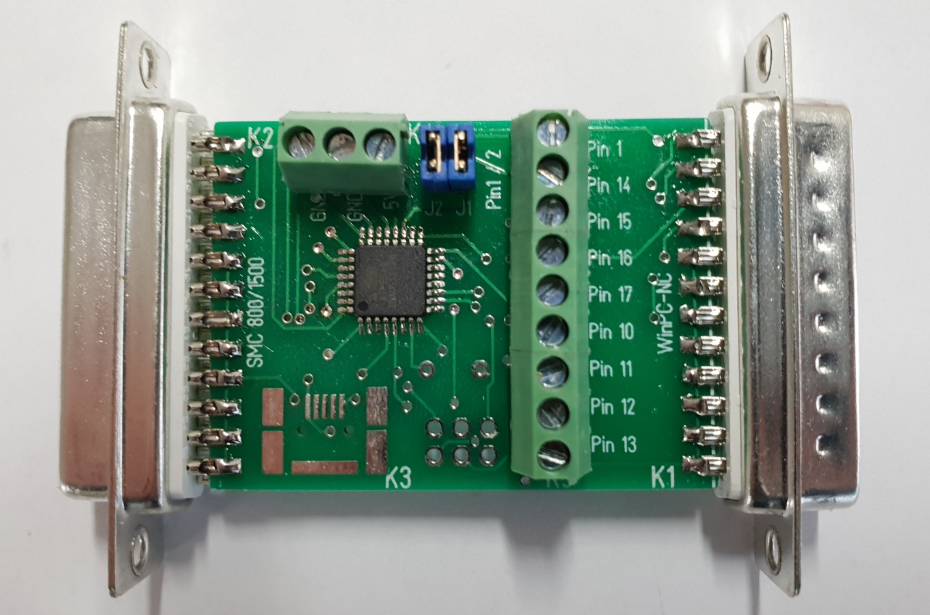

16.04.2020 - New function board SMC800/1500, WinPC-NC with SMC power stages Open or Close

Please note that previous versions of WinPC-NC could use SMC signals as well as the common clock pulse interface and directional interface for controlling power stages concerning the communication between CNC control and stepper motor power stages. The current versions WinPC-NC USB and WinPC-NC Professional do not support these old SMC signals automatically.

In the past SMC signals have often been used and there are still some mail order houses or specific shops where power stages can be purchased. SMC800 and SMC1500 from the Emis company are well-known examples for SMC power stages.

Up to now these users have been forced to replace the SMC power stage and to use a power stage with integrated clock pulse signal and directional signal, if they wanted to use another version of WinPC-NC or after loading an update. Our Step3S is perfectly made up for replacing SMC stepper motor power stages and provides some additional features and benefits.

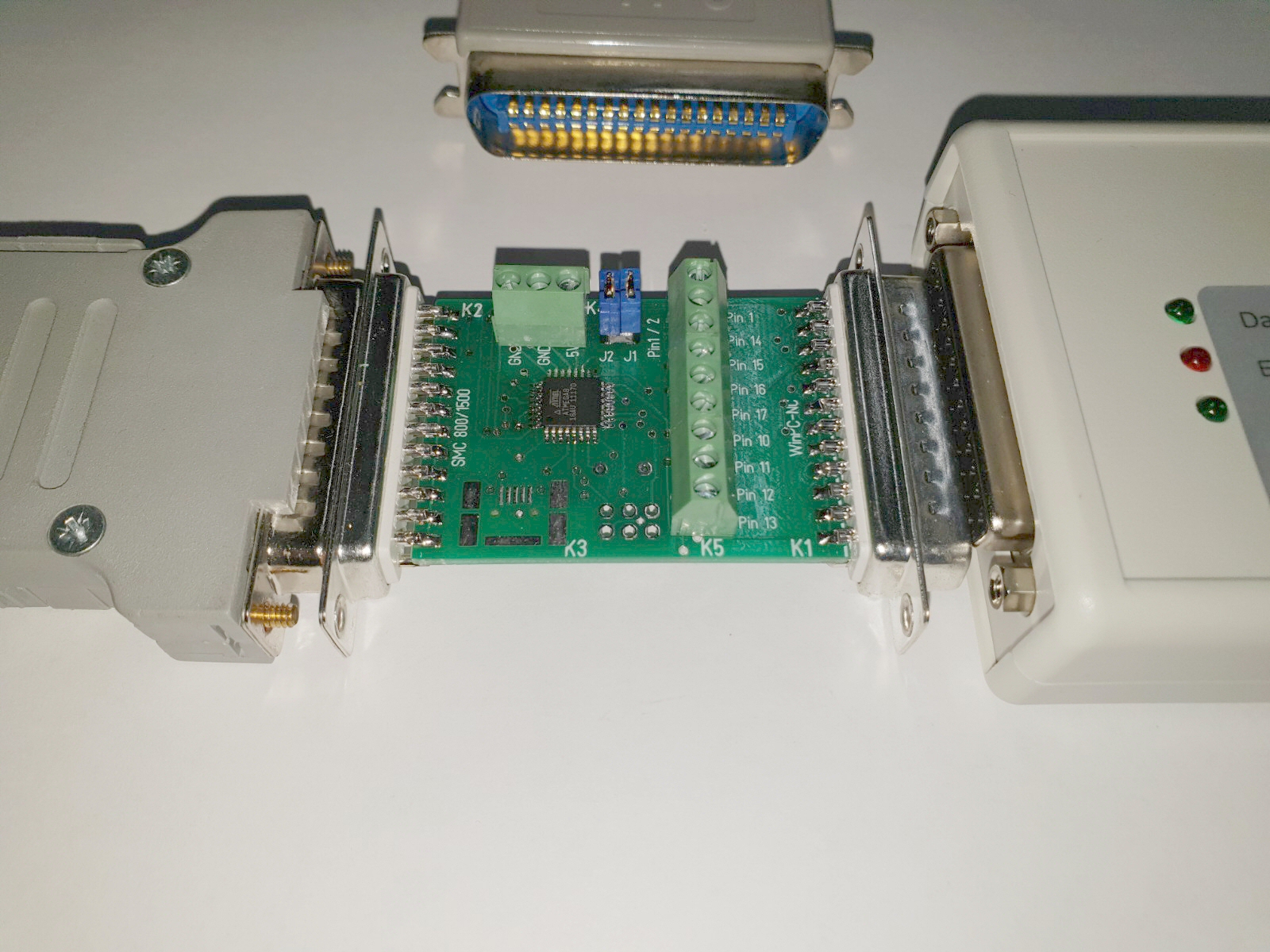

As we are always focused on best support of our customers, we developed a specific adapter, called SMC800/1500 adapter. This adapter is especially designed for users with SMC stepper motor cards and it allows a change to current versions of WinPC-NC without the necessity of purchasing a new stepper motor driver card. This device is available since this year. The adapter converts the clock pulse signals and directional signals into SMC signals. Additionally, the adapter provides terminals for 5 digital inputs of the 25pin interface of WinPC-NC, and, for example, it is possible to connect reference switches or height sensors.

The SMC800/1500 adapter is plugged between the 25pin interface of the WinPC-NC hardware and the 25pin connector of the SMC stepper motor driver card.

Contrary to the SMC800/1500 stepper motor cards which merely can be used by an input frequency of 5kHz, the SMC adapter allows independent and individual step resolution. By defining the number of steps per revolution of 200, 400 and 800, the user can define and obtain the perfect setting between rapid speed and position.

-

16.12.2019 - Merry Christmas and perfect start into the new year Open or Close

Happiness is the only thing that doubles when you share it.

We wish alle clients, partners and friends merry christmas and a perfect start into the new year 2020.

Please note that our office is closed from 23th december to the 6th january. During that time we are trying to answer your requests fast via e-mail.

Burkhard Lewetz

-

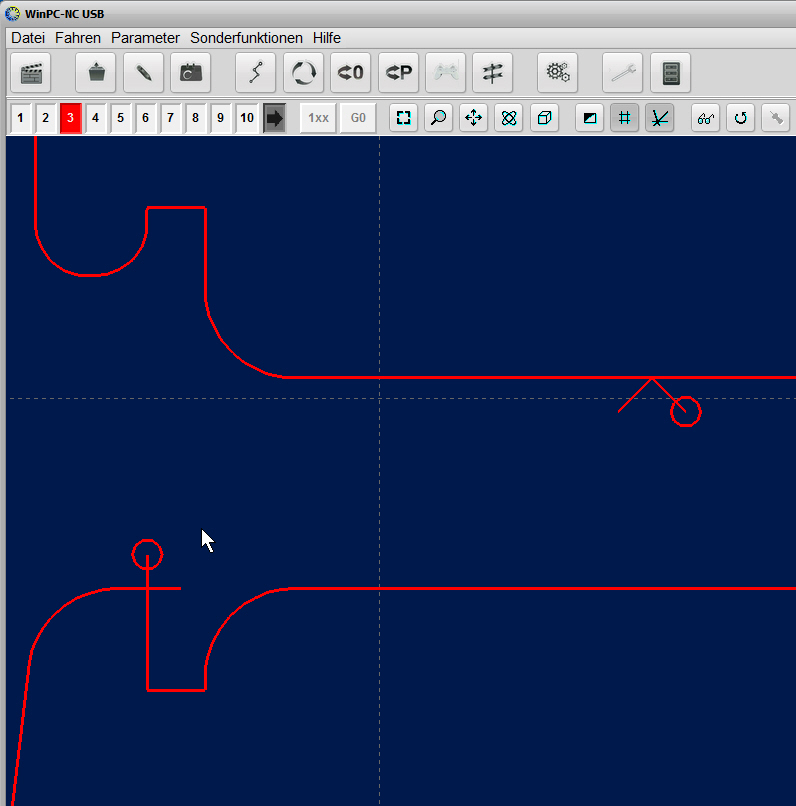

30.11.2019 - New Functions for WinPC-NC Open or Close

New version 3.40 of WinPC-NC has some brand new functions and a lot of minor fixes:

-

In 2D-CAM functions you can define aproach and leaving vectors for found contours.

- Also in 2D-CAM there is an option to compensate a dragging knife offset for cutting foil.

- Controlling of different laser heads now is much more accurate and reliable if PWM signal is used

-

-

12.08.2019 - WinPC-NC Version 3.40/29 is ready for download Open or Close

We have just published the revised WinPC-NC version 3.40 in the download center. This version provides further remarkable improvements for cutting and engraving lasering processes. Detailed information concerning the individual amendments can be obtained after each update in the menu ‘Help –This is new' in the WinPC-NC main menu.

As described here, you can proceed as usual for updating to the current version. Those customers who already utilize version 3.xx can directly load and use the update.

Customers who are still using the old version 2.xx but are interested in the advantages of version 3 can contact us via E-Mail for obtaining detailed information concerning the corresponding update from version 2 to 3. In order to provide complete and correct information please indicate your appropriate WinPC-NC serial number.

-

30.07.2019 - New function boards for analog signals and for controlling double drives for one axis Open or Close

With version WinPC-NC Professional, which is conceived for industrial use, it is possible for some time to control two drives synchronously for one axis direction. Furthermore, it is possible to generate a pure 0-10V analog signal due to expansion card EA160802 and Step 3S-card. Now we have also succeeded in realizing both functions for our other products by the PWM5V/10V board and the double axis board via an external hardware. Thus, these functions can also be used in WinPC-NC Light and WinPC-NC USB.

Both boards are conceived for being plugged in between the USB hardware and the machine electronics. This means less wiring complexity. Due to various options concerning configuration and a detailed description the corresponding in- and outputs on the board can be individually allocated to unassigned input and output pins. Thus it is not necessary to make any changes concerning the actual wiring or assignment and it is quite easy to upgrade these functions.

The signals for the individual functions can directly be connected on the board via integrated plug.

For further information please have a look at the manual which can be downloaded by the link below.

PWM-5V/10V board german manual (english manual will be available soon)

Current prices for the individual version can be found in the category ‘Accessories”.

-

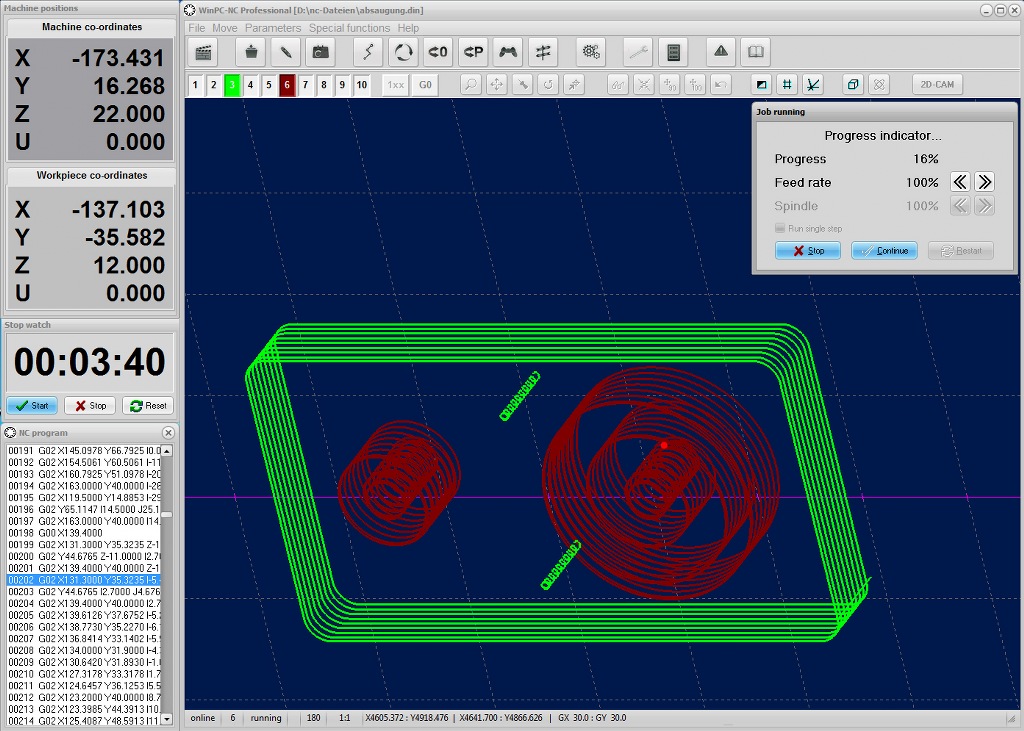

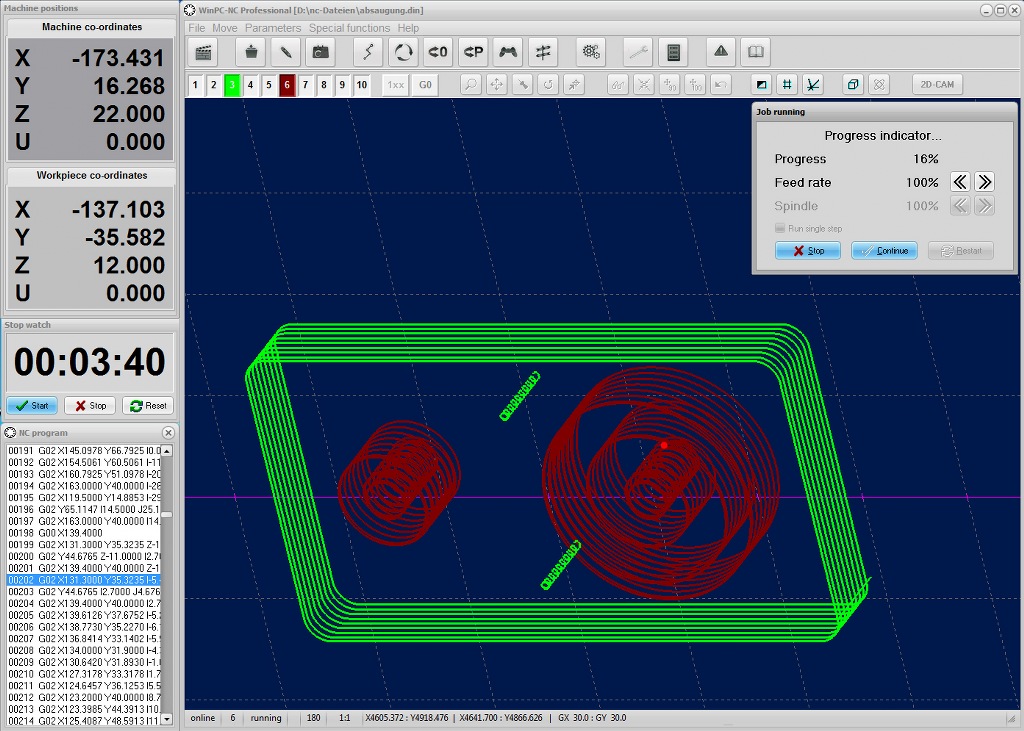

02.05.2019 - The new FILOU NC20 and Update Open or Close

With immediate effect a new version of the mostly used CAM program is available. It is called FILOU NC20 and it is highly popular among WinPC-NC users. Besides new functions, FILOU NC20 also provides an updated user interface with new icons and it makes quite an impression concerning many optimizations. A 30-day demo version is ready for download in the download center.

The new functions of FILOU NC 20 are indicated below:

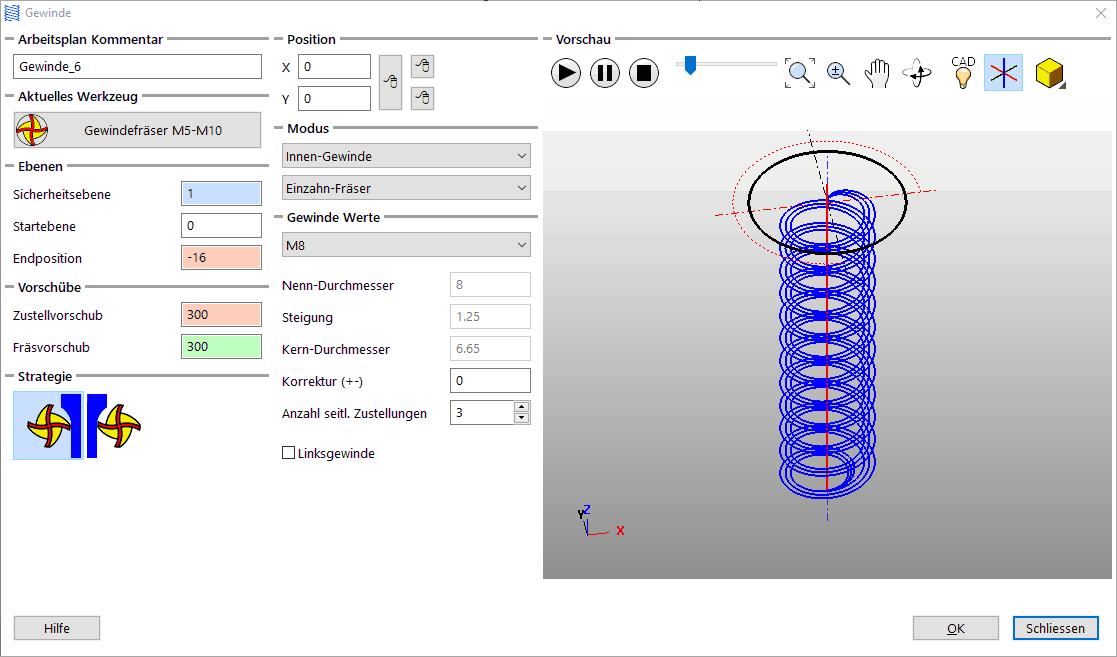

- Thread-milling

-

-

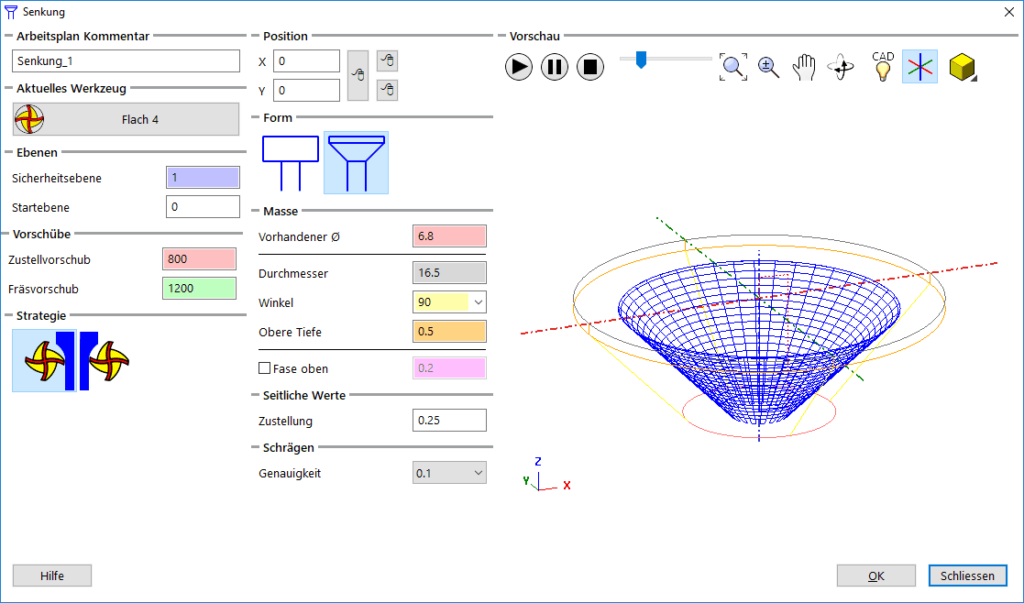

Countersink-milling

- Face-milling

- Oscillating along the contour

- Milling bridges during contouring

- ...and much more besides

Please note our price quotation including special discounts for updates from the old version to the latest version. This offer is valid until 31.05.2019.

- We offer a free update for all versions acquired after 01.07.2018. Please use our contact form or send us an e-mail indicating your complete address as stated at the time of purchase of Filou NC 16.

- Concerning old licences you can benefit from a 20 % discount for updating to the latest version of FILOU C20.

- You can benefit from a 50 % discount until 31.05.2019 on the upgrade price for ordering an advanced version.

System requirements:

- FILOU NC20 has been developed by Windows 10.

- Starting from Windows VISTA all other versions of Windows can be used.

- Support of Windows Tablet computers with touchscreen.

- 3D graphics requires OpenGL.

- Individual postprocessors of NC12 and NC16 can be further used.

- Filou NC20 can be installed in parallel to former versions.

-

26.04.2019 - WinPC-NC Version 3.40/05 is now available Open or Close

We published a new revision of WinPC-NC Version 3.40 today. The update can be loaded and installed like usual. You can find some detailled information of how to update you current installation here. The update can be loaded directly to all computers, which have already a running WinPC-NC version 3.xx installed.

The new functions of version 3.40 will be described more detailled in the how to section soon.

If you are stil using an old version 2.xx, please do not hesitate to contact us by mail for more information about the update from version 2.xx to 3.xx. Please do not forget to send us your WinPC-NC serial number with your request.

-

08.04.2019 - Actual changes and information concerning Handwheel/Pendant HR-10 Open or Close

For more than 3 years we provide a very user-friendly and comfortable solution for operating the machine without the necessity of using a keyboard or a mouse – the handwheel HR-10. This high-quality product can easily be handled as it feels very comfortable in the user’s hand. Top quality and the high standard of durability can be guaranteed by the production here in Germany.

Meanwhile it is unthinkable to use our testing machines without the handwheel, as operation can be extremely simplified. This is also confirmed by a repeated positive feedback.

Please note: Due to higher purchase prices we are unfortunately forced to raise the selling price (gross) for the handwheel to 229,00 €, applicable from 16.04.2019. However, orders received before 15.04.2019 are charged with the previous price.

Further information on the handwheel HR-10 can be obtained here.

-

29.11.2018 - Customer application with cutting laser Open or Close

As part of our discounted upgrade options to a more feature-rich version, it often happens that old WinPC-NC installation CDs have to be returned to us or destroyed. One of our customers sent us a nice and suitable for the cold season video in which he drives a cutting laser with his new WinPC-NC license.

-

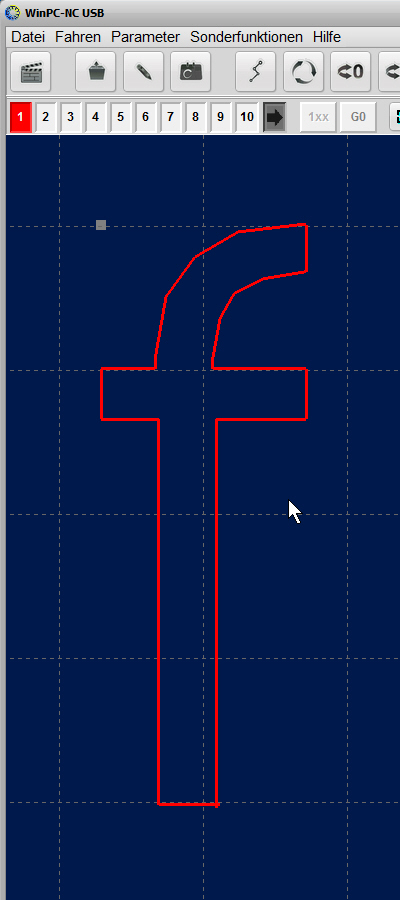

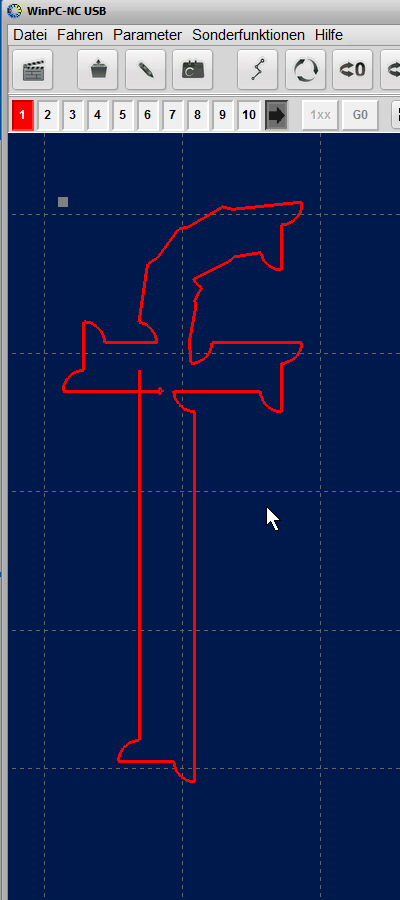

07.08.2018 - New functions for the operation of engraving and cutting lasers in WinPC-NC Open or Close

As part of version 3.01, WinPC-NC offers new functions for a more comfortable use of an engraving or cutting laser. With these functions, the parameters which are heavily dependent on the material when working with a laser can now be easily and intuitively determined and stored.

This saves time and costs by reducing first step failures.

The example picture shows a 0.2mm thick self-adhesive foil which was processed with the laser functions in WinPC-NC.

To make it easy to get started with the new functions, the first two WinPC-NC How does it work? Instructions for the new laser module are published today on our homepage in the help section. These describe in a PDF document how to connect a laser and set the parameters for operation in WinPC-NC. It also explains in detail how to perform the laser test to determine the material-specific parameters on a remnant.

We wish all users a lot of pleasure with the new WinPC-NC functions and technology.

-

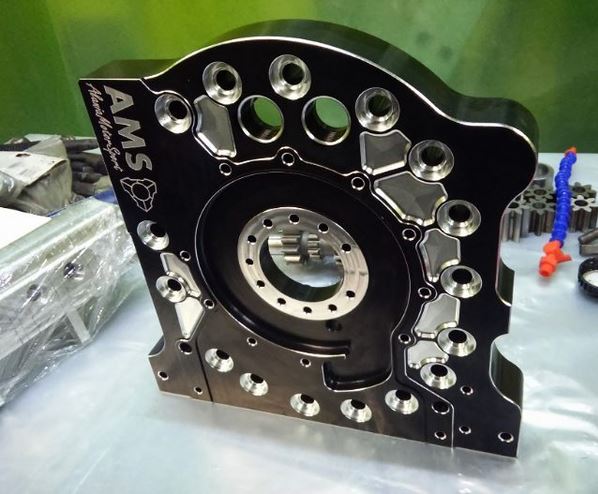

02.05.2018 - New customer pictures Open or Close

One of our customers and users sent us great pictures of his work made with WinPC-NC. He is a racing equipment supplier in Russia and is one of the top ten suppliers in his class.

Some of the pictures of Alania Motor Sport can be found here ...

https://www.instagram.com/antonsagdakov/

http://www.alaniamotorsport.ru -

30.03.2018 - Own CNC applications and references Open or Close

You can simply create your own CNC application with our hardware via the documented API interface

This week, we delivered a CNCCON-S axis controller to Microsoft via an American partner, directly to the Redmond headquarters near Seattle. The CNC machine in this application is controlled via the API programming interface with its own host program and is to be used in a test setup for tablet touch contacts.

The axis controller of WinPC-NC Professional has a documented programming interface and can easily be operated with your own software as an alternative to our WinPC-NC. Thus, the complete control of the machine can be exercised with your own software by sending simple commands to the API interface.

-

28.12.2017 - "WinPC-NC How does it work?" HowTo manuals Open or Close

"WinPC-NC Wie geht das?" und HowTo-Anleitungen

We have now created a FAQ-WinPC-NC How does it work? section with some How To manuals to provide an easy access to the CNC topic and further assistance with the re-entry or use of special additional components. We provide instructions for the installation, parameter transfer or the installation of an update for example. Furthermore, there are instructions for using the USB camera or the keypad for self sticking.

Further instructions and projects will follow.

-

27.12.2017 - Update from WinPC-NC version 2.X to 3.0 Open or Close

From the 12th January 2018 we charge a small fee of 59,- Euro for all WinPC-NC updates from version 2.X to 3.0, which were bought after the 1st October 2016. WinPC-NC licenses, which were bought before the 1st October 2016 can also be updated for a small fee of 59,- Euro. For more information please have a look into our price list.

Please notice, that all updates within version 3 are free again. Further informations about the changes in version 3 can be found here.

We need your full adress, serial number of software and serial number of USB hardware or axis controller for an update. Please send these information via e-mail to info@lewetz.de. We answer immediately with the next steps.

-

15.12.2017 - Merry Christmas Open or Close

We wish all our customers, users and partners merry christmas and a good start into the new year 2018. We would like to thank you for the good cooperation in the last year.

In this year it was a pleasure for us to integrate your wishes and suggestions in the new version 3.0 of WinPC-NC. We will continue there in 2018.

Burkhard Lewetz -

05.06.2017 - Hardware requirements version 3 / demo Open or Close

With the new version 3.0 the requirements to the PC hardware have increased. If you want to test the software before updating or ordering, you are invited to load the current demo of WinPC-NC version 3 here. This demonstration can be unpacked and started without installation and you can test the handlin, new graphical functions and even simulate a full job in real time. Machine controlling is simulated only.

-

29.05.2017 - WinPC-NC 3.0 and introduction price Open or Close

WinPC-NC 3.0 is now for all WinPC-NC Professional, WinPC-NC USB und WinPC-NC Starter versions available. Additionally we offer special introduction prices for our software.

WinPC-NC 3.0 has a lot of new features. An overview can be find here as PDF document.

To start easy, all profiles built in the 2.5 version, can be transfered into 3.0 version.

The Update from version 2.X to 3.0 is free for all license, that was bought after the 1st October 2016 (only for orders until the 12th January 2018, after 39,- Euro). The invoice number or the serial number on the CD is enough as proof. We deliver all other updates for a small fee of 39,- Euro. For more information please have a look into our price list. Please notice, that all updates within version 3.X are free again.

We need your full adress, serial number of software and serial number of USB hardware or axis controller for an update. Please send these information via e-mail to info@lewetz.de. We answer immediately with the next steps.

Introduction prices

To make WinPC-NC 3.0 even more attractive, we offer the following introduction prices:

Article Category of

shipping

costsIntroduction

price** (€) incl.

V.A.T.

gross amountIntroduction

price** (€) excl.

V.A.T.

net amountWinPC-NC new license WinPC-NC Light with nc100 1 149.00 125.21 WinPC-NC USB with ncUSB 2 279.00 234.45 WinPC-NC USB Upgrade from... WinPC-NC Starter with already existing Stepcraft USB module 0 159.00 133.61 WinPC-NC Light with already existing

nc1000 149.00 125.21 WinPC-NC Economy 2 129.00 108.40 Hardware change (only usb versions) ncUSB as change for nc100 2 59.00 49.58 ncUSB as change for Stepcraft USB

module2 99.00 83.19 ** The Introduction price is valid until 15. July 2017.

-

11.12.2016 – Merry Christmas Open or Close

We wish you a Merry Christmas and a perfect start into the new year.

Please note that our office is closed from 23th december to the 2th january 2017. During this time we will try to answer your question by e-mail.

-

07.12.2016 – Postprocessor for WinPC-NC in Fusion-360 Open or Close

Since now you can find a standalone WinPC-NC postprocessor for the great CAD/CAM program Fusion-360 of Autodesk under the following link.

https://cam.autodesk.com/posts/?p=winpc-nc